Product overview:

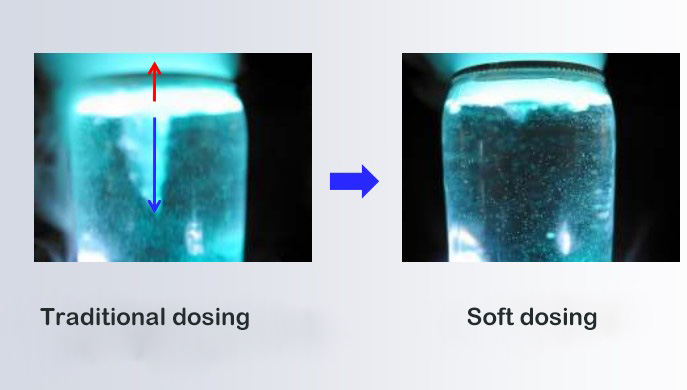

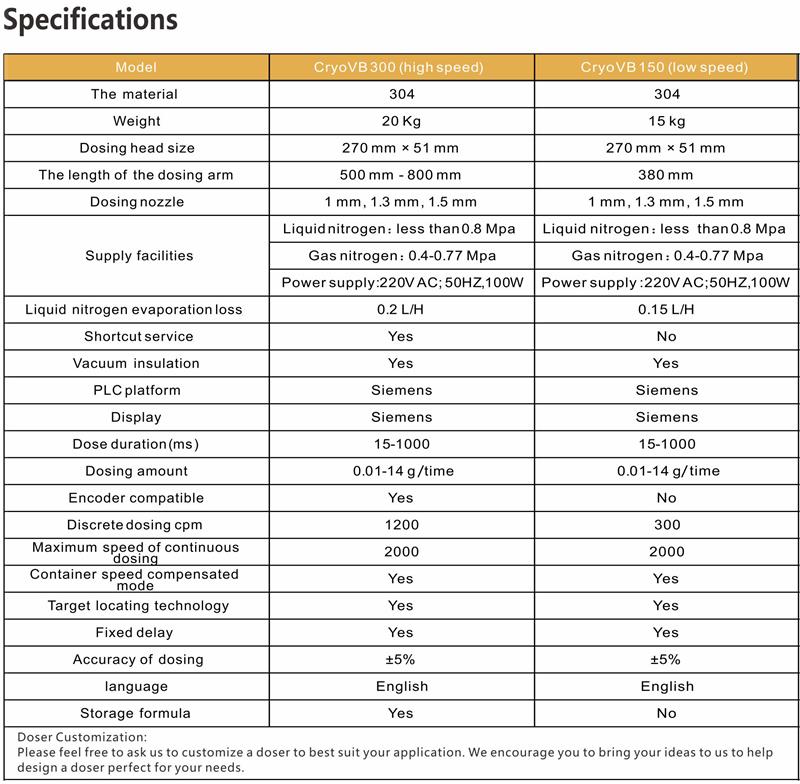

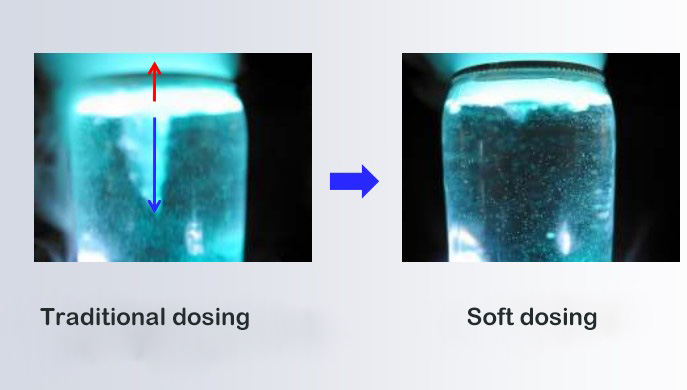

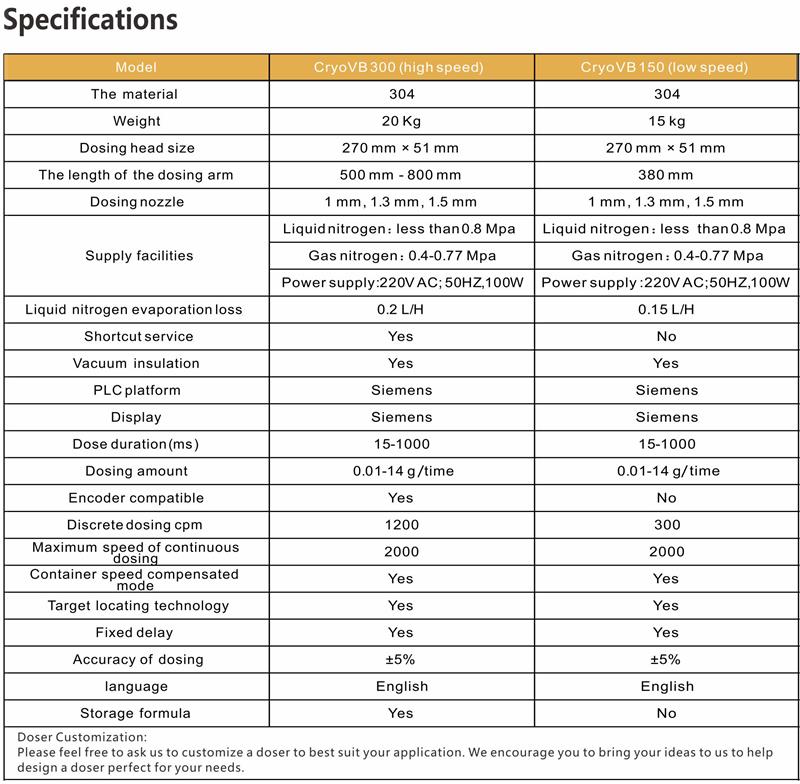

Liquid Nitrogen Dosing System has ability to serve every dosing application within one unit. It can be used from the slowest production lines to the fastest. It is offered with two controllers, high speed and low speed for options. LN2 is supplied to the doser by a vacuum insulated hose and flows into the dosing head. A sensor detects the speed of the line (encoder compatible for higher speeds), and a second sensor detects the presence of a container. When a container is detected, the dosing head actuated valve opens and dispenses the exact amount of pure LN2. A PLC (Programmable Logic Controller) is the brains behind integrating the sensors, controls and human interface via a touch-screen display.

Applications:

Pressurization in Packaging

A precise dose of liquid nitrogen is delivered immediately before capping or seaming. The trapped LN2 quickly vaporizes, pressurizing the container. In hot fill applications, the nitrogen pressure counteracts the vacuum created when a hot product cools.

Preservation

An exact dose of liquid nitrogen is introduced seconds before the seamer or capper. The small dose of liquid nitrogen gasified, 700 times its volume, in the process. The large volume of gaseous nitrogen pushed the oxygen out of the container.

Freezing

A dose of liquid nitrogen is introduced to “lock in” and surface freeze the product (novelty ice cream) before it’s transferred to a traditional tunnel or spiral freezer. Liquid nitrogen could enhance the taste and texture.

Key advantages

Lightweight PET – reduce the weight of PET for cost and environmental savings

Glass to PET transition – eliminate glass safety hazards and weight of containers

Container rigidity – maintain shape even with lighter weight containers

Eliminate paneling – increase the internal pressure to offset paneling issues

Oxygen reduction – create an inert environment to preserve product freshness

Extend shelf life – minimize oxygen levels

Ease of labeling – consistent container rigidity creates an efficient labeling process

Reduce nitrogen consumption – measurable and repeatable liquid doses

Maximize warehouse storage space – increasing product stackability utilizes less square footage

Stabilize organic products – extend shelf life without preservatives